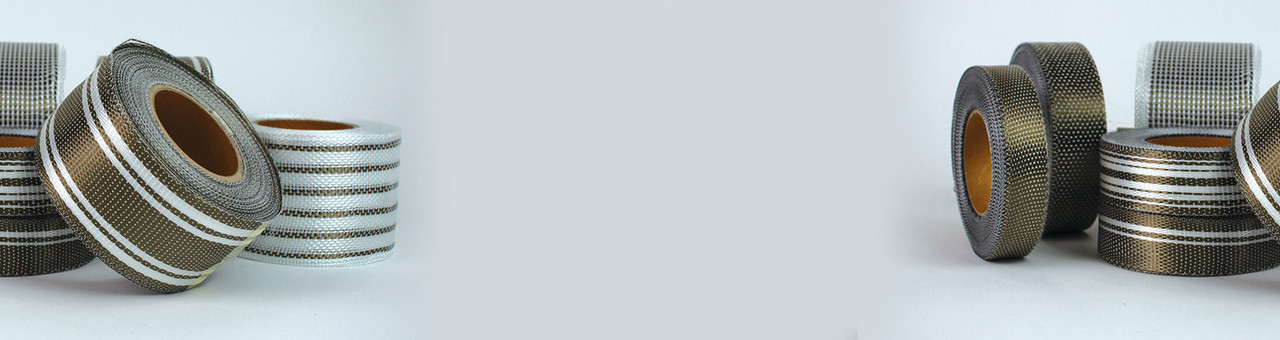

Basalt

Basalt Surfboard Hybrid Tape uses Shapers E-Glass surfboard glass and Basalt fibres. Basalt fibres are made from crushed Basalt rocks, which is one of the most commonly found volcanic rock in low to mid lining coast areas. Basalt in considered as an environmentally friendly product, as there no other materials required manufacture and does not need to be treated like other fibres. The manufacturing process is simple, Basalt is sourced, then washed, crushed, melted and then extruded into fibres.

FEATURES

Flex Properties similar to S-Glass with higher Impact Strength

High Impact Resistance

High Tensile Strength Increases Tail Strength

Naturally UV Resistant

Enhanced wet out ability with resin

Doesn’t em-brittle under high speed impact

Amazing strength-to-weight ratio

Basalt is a great alternative for manufactures that want more tail flex without compromising the natural flex of the foam, also with out losing integrity of impact and tensile strength.

INDUSTRY USES

Tail Patches

Basalt Tapes feature on the back rail of surfboards to prevent the tails from shattering and strengthening the deck from foot compressions.

Bottom of Surfboard

Basalt Tapes are also used on the bottom of the surfboards to create additional spring or pop out of the board. Known as Kitetic Flex

Full Rail of Surfboard

Basalt Tapes are often used along the full length of the surfboard rail with stringerless surfboards for added strength.

PU & EPS Compatible

Developed by Shapers Composites

Our Basalt Tapes are compatible with both EPS Epoxy and PU Polyester Resin.The Basalt Tapes are used during the lamination process. The tapes are placed on the foam before the cloth is laminated. Most manufactures mark the area they wish to place the Basalt Tapes, and brush a small amount of resin on the foam . The Basalt Tapes are then placed on the resin and then continue to lay the cloth over the board and laminate as normal.